With an increase in consumer awareness regarding what goes into developing cosmetic formulas—from choosing ingredients to the final package—it is imperative that manufacturers meet the demands of the present-day consumer, including the concept of “clean beauty.” Clean beauty encapsulates the concepts of sustainable, “green,” “natural,” and “eco-friendly,” etc., into not just cosmetic product development but also cosmetic product manufacturing processes, waste minimization and responsible sourcing to name a few.

It is very important to consider the actual benefits of clean cosmetic products so as to view it as an important venture being adopted within the cosmetic space.

Due to lack of harmonized definition for clean beauty, it is easy for anyone to make clean beauty claims on their cosmetic products. Ultimately, sustainability and safety uphold this agenda in the cosmetic space. The utilization of ingredients that are ethically sourced and that are sustainably harvested as well as ingredients that are safe to not just the consumer but also the environment at large are of utmost importance.

Sustainability Pros & Cons

In a bid to reduce the environmental damage Earth has been subjected to due to several human activities, sustainability has become a major focus across several industries including the cosmetic industry. Sustainability and safety champion the clean beauty movement and, as such, must be considered at all stages of product development. Considering sustainability at the different stages of the product lifecycle can be challenging. An example of one of these challenges is the detrimental utilization of palm oil for the production of surfactants.1 The cultivation of palm trees for this purpose is harmful to the eco-system because palm fruit farmlands are acquired through deforestation via bush/forest burning and it has been widely suggested that other agricultural produce, such as almonds, can be substituted for the production of these surfactants.

However, a much higher volume of almonds is required to produce the same volume of surfactants when compared to palm fruits; i.e., more almonds are required to produce the quantity of surfactants that would be obtained from using far fewer palm fruits. This becomes contradictory. In trying to conserve the land used to cultivate palm fruits by substituting with another crop, a larger part of the ecosystem is inevitably destroyed because more land is needed to plant this substitute crop to obtain the same output as with palm fruits. Also, there’s nothing sustainable about utilizing “natural” or “nature-derived” ingredients from plants as opposed to chemically synthesized ingredients when the plants being used aren’t cultivated or harvested in a sustainable fashion. Some plants are peculiar to certain regions of the world and it is almost impossible to supply this ingredient to the cosmetics industry when demand is high. Therefore, it is critical to conduct detailed analysis of the environmental footprint based on the entire product lifecycle and ensure adherence to the principles of green chemistry and green engineering.2-4

Substitution Challenges

The challenge of developing clean beauty products does not end with the identification of truly sustainable and ethically-sourced ingredients which adhere to all principles of green chemistry and manufacturing them according to green engineering principles. These new ingredients create a whole new set of formulation development challenges. There is the possibility of substantial performance limitations when formulating with ingredients that are considered the “clean, more sustainable alternative” ingredients. In a bid to achieve more sustainable products, ingredients that are considered toxic are substituted for “clean” ingredients. However, these clean ingredients may not necessarily impart high levels of performance in formulation as their “synthetic” counterparts.

This is a major issue as cosmetic products must deliver on their claims as stated by the manufacturers; ingredient substitution cannot impact the finished product’s efficacy. Substituted ingredients must equal or surpass the performance of their counterparts. Issues with rheology build, emulsion stability, foam quality and cleansing may arise, as well as the delivery of positive sensorial attributes with these clean ingredients.

These undesirable results may not necessarily occur because the clean ingredients are inauthentic or ineffective; rather, there isn’t vast research and formulating experience with most “clean” ingredients to enable formulators to work toward a desired result, nor troubleshoot formulation issues that may arise. Most clean ingredients haven’t been utilized as frequently as common ingredients and, as such, have not been subjected to formulating conditions such as varying pH ranges, electrolyte effects, mixing shear rates and temperatures, which ultimately inform the formulator on how these ingredients may perform under these conditions on an ongoing basis. This will improve with time. As more brands utilize clean ingredients, new formulation design rules will emerge that will guide other formulators toward developing high-performing desirable products.

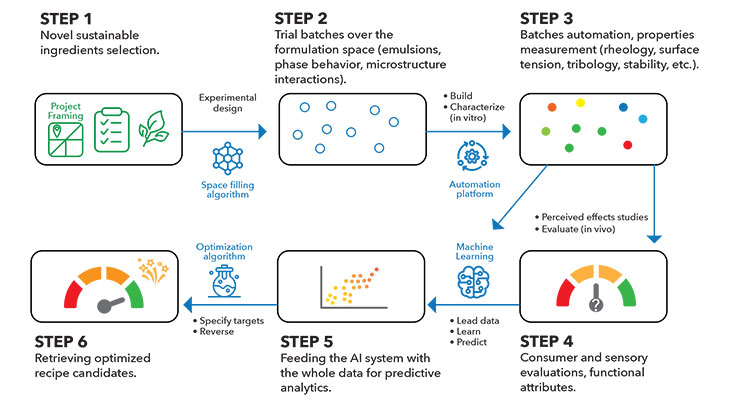

The wide range of possibly sustainable, ethically sourced and safe ingredients from multiple suppliers makes the correct choice of the ingredient and the formulation optimization exercise highly challenging. What is required is a smart formulation design protocol allowing fast prototyping and testing. This approach is highlighted in the schematic on p. 52 (see Figure 1).

Figure 1

The approach highlighted here is based on a knowledge-based optimization through connecting phase behavior, interactions and microstructure in novel ingredient containing formulations to relevant physico-chemical properties and eventually to the consumer sensory and functional attributes. This process can be rapidly enhanced through the utilization of automation, AI and Machine Learning as highlighted in the following paragraphs.

Automation Improves Processes

Automated formulation platforms enable one to perform complex formulation workflows in a fully automated manner. Its unprecedented accuracy and ability to perform multiple formulations with changing or different variables simultaneously makes it easier to perform tasks in shorter periods of time and under very little supervision. Its advantages over manual formulation include, but are not limited to, continuous real-time monitoring and control of all formulation parameters, including internal and jacket temperature, shear rate and viscosity, scraping speed, reflux and pH in an inert atmosphere, if desired, automatic logging of all data.5

With the above listed capabilities, it’s very possible to study and determine many characteristics of emerging clean ingredients. This will reduce greatly the time to market for a lot of product offerings from clean beauty brands. Being able to subject ingredients in formulation to multiple varying parameters at the formula development stage within a short period of time, yet still maintaining precision and accuracy of techniques throughout the process, is key to building innovation within this space.

AI and ML Accelerate Personalization

Data is the new oil, automation is the new drilling platform and AI is the new power! The formulation of novel sustainable ingredient without compromising cosmetic product performance is a great challenge. The interactions occurring between components within the formulation are extremely hard to predict using typical chemistry and physics principals. Even if automation platforms greatly enhance the number of experimental trials, the extensive formulation space dimension and the lack of knowledge surrounding the interactions between formulation constituents make it difficult to control the mechanical and physiological behavior of the blends; e.g., emulsion stability. This is of significant concern when considering time-consuming evaluations that aren’t easy to automate, such as shelf-life, challenge tests, in vivo efficacy, safety and so on. In addition, the large number of experimental data carried out through automation platform can’t be handled without easy-going statistical toolboxes.

Therefore, the development of cosmetics in an eco-sustainable formulation process, remains a constant industrial stake without additional tools.

Statistical software, such as experimental design based (A. Fisher, 1964), have solved simple formulations and process parameters problems. Conversely, the postulates are too simplified on the linearity or continuity of the phenomena; e.g., chemical bond rupture and formation; and therefore, provide mechanisms that are too simplistic for the formulas. Advances in artificial intelligence, in particular machine learning,6-8 have promoted computer-aided design9 that can be coupled to an automation platform in order to generate much more predictive insights over the formulation domain. Machine Learning makes it possible to model complex non-linear, discontinuous cause-and-effect relationships between the constituents of the formula, the process parameters and the properties of the formula with a limited set of experiments.

These on-going strategies, digital, algorithms and hardware are opening tremendous paths to a bright future for clean beauty.

References

- What is sustainable palm oil? https://www.eco-business.com/news/what-is-sustainable-palm-oil/ (2017).

- Anastas, P. T.; Warner, J. C. Green Chemistry: Theory and Practice, Oxford University Press: New York, 1998.

- Benhur, A. M., Pingali, S., & Amin, S. (2020). Application of Biosurfactants and Biopolymers in Sustainable Cosmetic Formulation Design. Journal of Cosmetic Science, 71(6), 455-480.

- Drakontis, C. E., & Amin, S. (2020). Biosurfactants: Formulations, properties, and applications. Current Opinion in Colloid & Interface Science.

- Chemspeed Technologies. www.chemspeed.com (2019)

- Breiman, L. Machine Learning (2001). https://doi.org/10.1023/A:1010933404324

- Cortes, C. & Vapnik, V. Mach Learn (1995). https://doi.org/10.1007/BF00994018

- F. Rosenblatt. The perceptron, a perceiving and recognizing automation Project Para. Cornell Aeronautical Laboratory, 1957.

- InFLOWS AI. www.inflows-ai.com (2020).

- Kane A. et al. Improving the parameters of a global ocean biogeochemical model via variational assimilation of in situ data. Journal of Geophysical Research (2011).

Davies Aina Radiance Davies has a Master’s Degree in chemical engineering with a focus in cosmetics engineering from Manhattan College. Her research interests include automated formulation design for novel textures and superior performance of hair care and skin care cosmetic products. She is the principal R&D scientist at her start-up, RD8 Labs, which aims to be Nigeria’s foremost cosmetic and biopharmaceutical research, formulation and advanced characterization laboratory.

Abdou Kane has more than 12 years of experience in AI, digital and data strategy. He has done award-winning AI-driven projects for beauty personalization. IT and solution architect across several large-scale industries, including cosmetics and food. As a former data science manager at L’Oréal Research and Innovation, he went through developing from scratch AI-based toolboxes for cosmetic labs. During this journey, he set up the strategy and led the team which fully developed/deployed cutting-edge tools with access provided up to 500 researchers worldwide, enhancing collaboration across continents and dividing by up to 6 the time to fix formula recipes. Currently, as the chief AI officer of InFlows, Kane leads the innovation and development of next-generation software that embed artificial intelligence breakthroughs to accelerate chemical product formulation.

Samiul Amin is currently associate professor of chemical engineering at Manhattan College, where he leads the cosmetic engineering focus area. Prior to joining academia in March 2018, Prof. Amin has worked in industry for the past 20 years working across engineering, R&D and innovation management in global multinationals such as ExxonMobil, Unilever, L’Oréal and Malvern Instruments in Asia, Europe and the US. His areas of expertise are formulation design, sustainable cosmetic formulations and advanced characterization.

Original Link: https://www.happi.com/contents/view_features/2021-05-04/sustainable-personal-care-formulations/